Product Category

Process Industries

Product

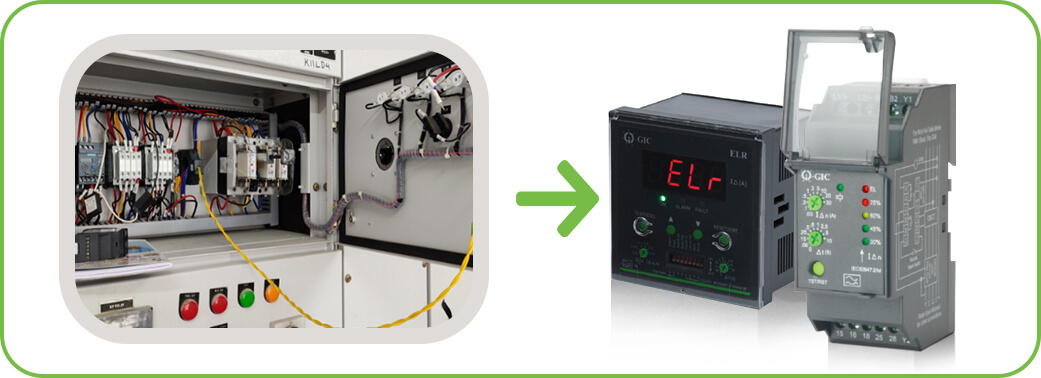

Digital ELR 17K716QF4N with CBCT

Application

In MCC (Motor Control Centre) panel of stone crushing machines at cement manufacturing site.

Safety Hazards? Not on our watch! GIC’s ELR makes Stone Crushing Machines Safer

Introduction

Enhancing safety and efficiency in cement manufacturing, GIC’s Digital ELR (17K716QF4N) with CBCT finds a crucial application in the Motor Control Centre (MCC) panels of stone crushing machines With the demand for cement soaring, the cement plant’s raw material crushing process becomes a pivotal point in its operations. GIC’s cutting-edge solution steps in to address the challenges that arise during this critical phase, ensuring seamless and secure operations.

Challenges

Operating in a high-stakes environment, cement plants face significant hazards and health risks, including electrical short circuits, fires, and potential tripping of the entire power supply. These threats not only hampered production but also posed a grave risk to the safety of workers on-site. The detection of ground fault currents before they could lead to harm became a pressing need for the plant’s operational continuity and the protection of human lives and machinery.

Solution

GIC’s Digital ELR with CBCT was successfully installed at various cement manufacturing plants across the country, empowering their stone-crushing machines with superior safety measures. The implementation has resulted in a safer and more productive cement manufacturing process, showcasing the effectiveness and value of GIC’s advanced electrical protection solutions.

GIC’s Digital ELR offered an intelligent and comprehensive solution to mitigate the challenges faced during the cement plant’s material crushing process. Continuously monitoring and displaying leakage current in the electrical system, the ELR allowed for the flexibility to set leakage current levels from 30mA to 30A based on specific application requirements. The incorporation of core balance current transformer (CBCTs) further enhanced its efficiency, enabling the passage of conductors of any size.

In the event of an earth fault occurrence, the ELR instantly detects it and activates the trip coil of MCCB/ACB/OCB/Contactor, promptly isolating the electrical power system. This rapid response mechanism significantly reduced the risk of electrical accidents, protecting both workers and valuable assets within the plant.

The GIC Effect

Human Safety Assurance: GIC’s Digital ELR acts as a vigilant guardian, detecting and isolating electrical faults before they pose any danger to the workforce, ensuring the safety of personnel at the cement plant.

Asset Protection: With its exceptional ground fault current monitoring, the Digital ELR actively prevents fires, safeguarding critical assets and ensuring uninterrupted cement plant operations.

Cutting-edge Solution: GIC’s Digital ELR represents the forefront of safety technology, designed to meet the rigorous demands of industrial environments and provide unparalleled protection.

Optimize Operations: By proactively identifying and addressing electrical risks, the Digital ELR enables cement manufacturers to streamline their operations, minimize downtime, and enhance productivity.

Seamless Material-Crushing: With GIC’s Digital ELR guarding the electrical system, cement manufacturers can carry out the material-crushing process with utmost confidence, ensuring a smooth and uninterrupted cement production cycle.