Product Category

HMI, Process Controls, Power Supplies

Product

HMI, PLC, SMPS

Application

Powder Coating Plant

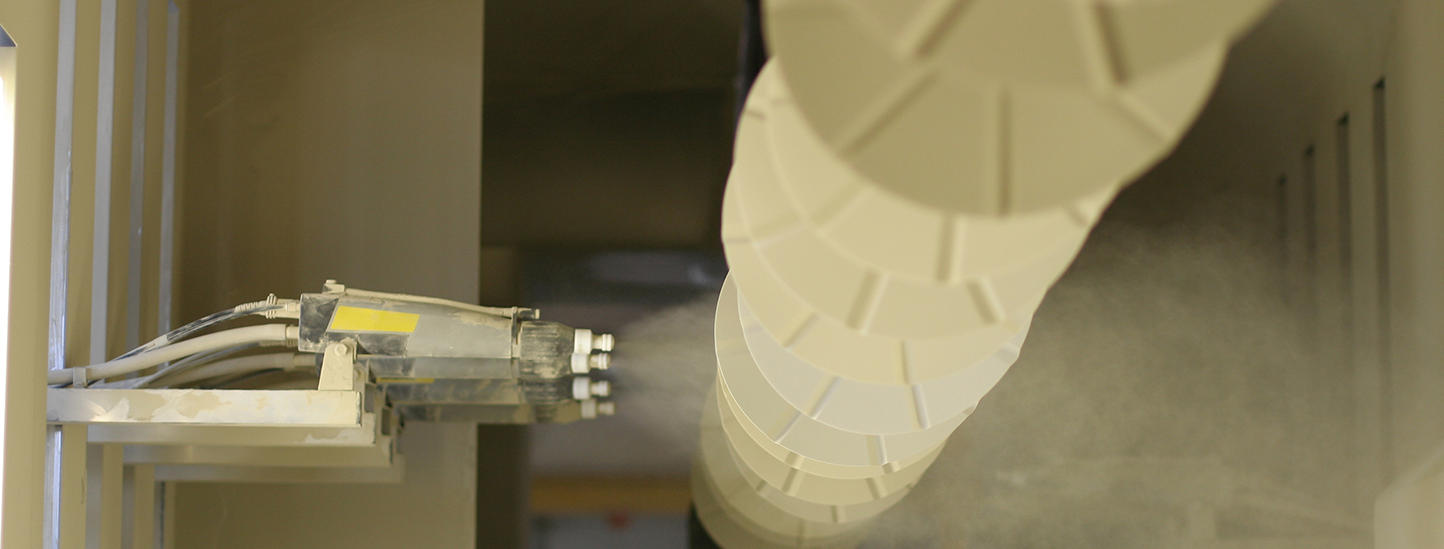

Elevating Excellence in Powder Coating Plant through GIC’s PLC & HMI

Introduction

A powder coating plant is a dedicated facility for applying dry finishes to various surfaces. In this process, finely ground particles of pigment are electrostatically charged and sprayed onto a surface. This case study talks about how GIC products play an important role in the smooth functioning of automatic powder coating.

Challenges

Running a manual powder coating plant presents unique challenges and demands specific operational considerations.

- Consistency & Efficiency

- Wastage and Overspray

- Quality Control

- Labour Intensive

- Health and Safety Concerns

- Workflow Management

Solution

- GIC’s PLC and HMI control systems are vital for running automatic powder coating plants.

- They enable seamless operation, monitoring, and control of plant components and processes.

- Integration of GIC’s PLCs and HMIs ensures high automation, precision, and centralized management.

- Operators can oversee the entire plant from a single interface, ensuring efficient production and quality control.

Result

GIC’s products help the powder coating plant to attain features like-

Consistency and Quality

Reduced Material Waste

Increased Efficiency

Lower Labour Costs

Enhanced Overall Productivity

Improved Safety

Precision and Control

Data Collection and Analysis

The GIC Effect

Cost-Effective Solution.

After-Sales Service Support.

Made in India Product.

Committed for quality product with CE, ROHS certification.

Since ISO Certified organization.