Product Category

HMI, Process Controls

Product

HMI, TC, PLC

Application

Ethylene Oxide Sterilizers

Achieving Optimal Sterilization with PLC, TC, and HMI

Introduction

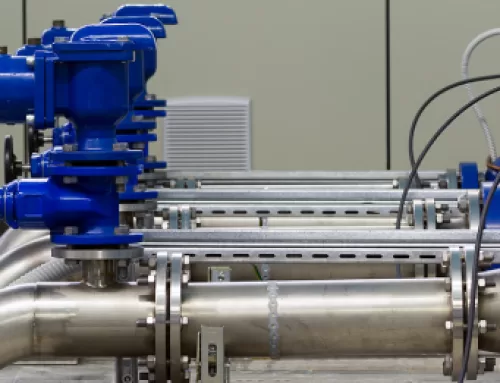

Ethylene Oxide (ETO) sterilizers are essential for sterilizing medical equipment and supplies that are sensitive to heat and moisture. ETO gas is a highly effective sterilizing agent capable of penetrating porous materials and eliminating microorganisms such as bacteria, viruses, and spores.

Challenges

- Inconsistent Sterilization: Manual and semi-automatic methods often lead to inconsistent sterilization, risking incomplete elimination of harmful microorganisms.

- Process Efficiency: Traditional methods can be time-consuming, impacting the turnaround time for sterilized equipment.

- Resource Utilization: Inefficient use of ETO gas and energy in non-automated systems.

- Safety Concerns: Manual handling of ETO gas poses significant safety risks to operators.

- Regulatory Compliance: Ensuring compliance with stringent regulatory standards for sterilization processes.

Solution

To address these challenges, GIC made easy the implementation of an automated ETO sterilizer system utilizing the PL100 PLC, TCS1T100 Temperature Controller, and HMI.

PLC Control (PL100): Acts as the central control unit, automating the entire sterilization process from start to finish. It ensures precise control and monitoring of critical parameters, enhancing process consistency and safety.

HMI Interface: Provides an intuitive platform for operators to interact with the sterilizer. It allows for easy setting of sterilization parameters, monitoring of cycle progress, and real-time feedback.

Temperature Controller (TCS1T100): Ensures precise temperature regulation within the sterilization chamber, working in conjunction with the PLC to maintain the desired temperature range throughout the sterilization cycle.

The GIC Effect

Implementing GIC’s automated ETO sterilizer system has led to several significant improvements:

Cost effective solution – GIC’s solution provides cost-effective automation, ensuring maximum value for investment.

After sales service support – A commitment to customer satisfaction with robust after-sales service.

Made in India Product – GIC’s products are proudly manufactured in India.

Committed for quality product with CE, ROHS certification

Since ISO Certified organization – Operating as an ISO-certified organization, GIC ensures adherence to global standards.